We have provided outstanding cleaning services for years. Our knowledgeable technicians are dedicated to excellence in every project.

Selective Catalytic Reduction (SCR) Systems Cleaning

Selective catalytic reduction (SCR) technology fulfills the valuable function of reducing harmful emissions. These advanced active emission control systems significantly reduce nitrogen oxide levels (NOx), which contribute to smog. The regular use of SCR systems frequently results in system plugging or damaging contaminant buildups forming inside the equipment and decreasing performance.

At EAI Industrial Services, we provide SCR cleaning services to keep your valuable equipment functioning optimally. We’re a reputable industrial cleaning company serving the private and public sectors in the U.S. since 1989. Our turnkey solutions improve equipment performance while meeting health, safety and environmental regulations. We have a highly experienced and trained team and use efficient cleaning methods to meet your expectations.

What Does the SCR Catalyst Do?

If catalyst components are not cleaned, the ammonia injection system will not be tuned, and ammonia slip can occur. The combination of this ammonia slip and contaminants in the fuel leads to the formation of ammonia salts downstream. The result is that they often create thick deposits on the gas side of the fin tubes, which reduces heat transfer efficiency and promotes corrosion on the back end of the heat recovery steam generator (HRSG).

Since catalyst systems contain potentially hazardous contaminants, regular cleaning techniques are not safe or effective for these vital parts. Utilizing air lancing and vacuuming to clean these systems ensures the process is safe, effective and environmentally friendly. This cleaning method is ideal for delicate industrial components like SCR catalyst systems. It minimizes plug formations and helps extend the systems’ life span.

|

|

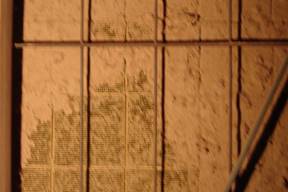

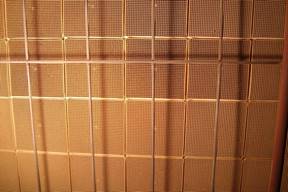

| Catalyst prior to cleaning | Catalyst after cleaning |

Why Is SCR System Cleaning Important?

If catalyst components are not cleaned, the ammonia injection system will not be tuned, and ammonia slip can occur. The combination of this ammonia slip and contaminants in the fuel leads to the formation of ammonia salts downstream. The result is that they often create thick deposits on the gas side of the fin tubes, which reduces heat transfer efficiency and promotes corrosion on the back end of the heat recovery steam generator (HRSG).

Since catalyst systems contain potentially hazardous contaminants, regular cleaning techniques are not safe or effective for these vital parts. Utilizing air lancing and vacuuming to clean these systems ensures the process is safe, effective and environmentally friendly. This cleaning method is ideal for delicate industrial components like SCR catalyst systems. It minimizes plug formations and helps extend the systems’ life span.

How We Clean SCR Catalyst Systems

Traditional cleaning methods for SCR catalyst systems rely on using expensive, often hazardous chemicals. EAI’s air lancing is the best cleaning method for these components. It is a gentle, environmentally friendly way to clean all the delicate components of your SCR, safely and effectively.

Our experts use compressed air to loosen dust, grease, and other contaminants from SCR catalyst systems. The vacuum component then removes the dislodged debris with the help of a powerful motor and a suction mechanism and moves it to the collection container.

The air lance features a nozzle design, enabling targeted cleaning of specific areas. This gentle method protects component integrity while delivering a thorough cleaning. Its adjustability allows us to apply the correct amount of air pressure to the system.

How Does SCR Catalyst Cleaning Affect Your HRSG?

With regular use, the steam generator’s exhaust gas transports dust, dirt and contaminants, which eventually build up to create a plug. This accumulated debris causes elevations in back pressure and reduces the plant’s capacity. Insulation failures upstream quickly coat the catalyst’s surface and restrict the smooth flow through the HRSG.

Regularly cleaning and scouring your SCR catalysts ensures that your HRSG operates at maximum capacity and full effectiveness. Once the restrictive plug is removed, the equipment will function optimally as a result of the following:

- Increased surface area for catalytic reduction

- Lower ammonia slip percentage

- Improved catalyst life span

- Reduced back pressure

- Enhanced plant efficiency and reliability

Why Choose SCR Cleaning Services From EAI?

After years of using air lancing and vacuuming to clean SCR catalysts for our clients, we can confidently say that it’s the most effective and safe method for cleaning these vital emission control systems.

Our SCR cleaning benefits include access to the following:

Using air lancing for SCR systems is environmentally friendly since it is chemical-free and doesn’t release contaminants into the air.

We’ll mobilize our equipment in emergencies or when you require unscheduled cleaning.

We understand that each setting is unique, which is why we tailor solutions to fit your facility’s specific requirements.

Our MSTs can be quickly mobilized in emergencies or when unscheduled cleaning is required.

We understand each setting is unique, which is why we tailor cleaning solutions to fit your facility’s specific requirements.

Our services reduce back pressure and improve heat transfer efficiency, enhancing output and making your SCR catalyst system last longer.

Boost Your SCR Catalyst System’s Output With Cleaning Services From EAI

Take advantage of EAI’s SCR catalyst cleaning services and optimize your equipment’s performance. Our experienced team provides the best environmentally friendly solutions at cost-effective rates. Restoring lost HRSG performance and boosting your organization’s efficiency may be as simple as keeping your system free of contaminants and plugs that may be hampering output.

Experience our exceptional customer service and find out for yourself why our client portfolio includes multiple high-profile industrial companies and federal government agencies.

To learn more or request a quote, contact us today!